Basic Introduction or Principle: We all are aware with the term "Generator". A device which converts mechanical energy into electrical energy is known as generator. This generator makes rotate with the help of some kind of external energy. When this energy extract from the energy of steam, the plant is known as steam power plant. A simple steam plant works on Rankine cycle. In the first step, water is feed into a boiler at a very high pressure by BFP (boiler feed pump). This high pressurized water is heated into a boiler which converts it into high pressurized super heated steam. This high energized steam passes through steam turbine (a mechanical device which converts flow energy of fluid into mechanical energy) and rotate it. Owing to extract full energy of steam, three stage turbines is used which is known as LPT (Low pressure turbine), IPT (intermediate pressure turbine) and HPT (High pressure turbine). The turbine shaft is connected to the...

Today we will discuss about engine and types of engine used in automobile. Any device which can convert heat energy of fuel into mechanical energy is known as engine or heat engine. Engine is widely used in automobile industries or we can say that engine is the heart of an automobile. Basically engine may be classified into two types.

Types of Engine:

1. External combustion (E.C.) Engine

It is an engine in which combustion of fuel take place outside of the engine. In this type of engine heat, which is generated by burning of fuel is use to convert the water or other low boiling temperature fluid into steam. This high pressure steam used to rotate a turbine. In this engine we can use all solid, liquid and gases fuel. These engines are generally used in driving locomotive, ships, generation of electric power etc.

Advantages of E.C. engine-

- In these engines starting torque is generally high.

- Because of external combustion we can use cheaper fuels as well as solid fuel.

- They are more flexible compare to internal combustion engines.

2. Internal Combustion (I.C.) Engine

It is an engine in which combustion of fuel take place inside the engine. When the fuel burns inside the engine cylinder, it generates a high temperature and pressure. This high pressure force is exerted on the piston (A device which free to moves inside the cylinder and transmit the pressure force to crank by use of connecting rod), which used to rotate the wheels of vehicle. In these engines we can use only gases and high volatile fuel like petrol, diesel. These engines are generally used in automobile industries, generation of electric power etc.

Advantages of I.C. engine-

- It has overall high efficiency over E.C. engine.

- These engines are compact and required less space.

- Initial cost of I.C. engine is lower than E.C. engine.

- This engine easily starts in cold because of it uses high volatile fuel.

Types of I.C. Engine

I.C. engine is widely used in automobile industries so it is also known as automobile engine. An automobile engine may be classified in many manners. Today I am going to tell you some important classification of an automobile engine.

According to number of stroke:

In a two stroke engine a piston moves one time up and down inside the cylinder and complete one crankshaft revolution during single time of fuel burn. This type of engine has high torque compare to four stroke engine. These are generally used in scooters, pumping sets etc.

In a four stroke engine piston moves two times up and down inside the cylinder and complete two crankshaft revolutions during single time of fuel burn. This type of engines has high average compare to two stroke engine. These are generally used in bikes, cars, truck etc.

According to design of engine:

1. Reciprocating engine (piston engine)

In reciprocating engine the pressure force generate by combustion of fuel exerted on the piston (A device which free to move in reciprocation inside the cylinder). So the piston starts reciprocating motion (too and fro motion). This reciprocating motion converts into rotary motion by use of crank shaft. So the crank shaft starts to rotate and rotate the wheels of vehicle. These are generally used in all automobile.

2. Rotary engine (Wankel engine)

In rotary engine there is a rotor which frees to rotate. The pressure force generate by burning of fuel is exerted on this rotor so the rotor rotate and starts to rotate the wheels of vehicle. This engine is developed by Wankel in 1957. This engine is not used in automobile in present days.

According to fuel used:

1. Diesel engine

These engines use diesel as the fuel. These are used in trucks, buses, cars etc.

2. Petrol engine

These engines use petrol as the fuel. These are used in bikes, sport cars, luxury cars etc.

3. Gas engine

These engines use CNG and LPG as the fuel. These are used in some light motor vehicles.

4. Electric engine

It is eco-friendly engine. It doesn’t use any fuel to burn. It uses electric energy to rotate wheel.

According to method of ignition:

1. Compression ignition engine

In these types of engines, there is no extra equipment to burn the fuel. In these engines burning of fuel starts due to temperature rise during compression of air. So it is known as compression ignition engine.

2. Spark ignition engine

In these types of engines, ignition of fuel start by the spark, generate inside the cylinder by some extra equipment. So it is known as spark ignition engine.

According to number of cylinder:

1. Single cylinder engine

In this type of engines have only one cylinder and one piston connected to the crank shaft.

2. Multi-cylinder engine

In this type of engines have more than one cylinder and piston connected to the crank shaft.

According to arrangement of cylinder:

1. In-line engine

In this type of engines, cylinders are positioned in a straight line one behind the other along the length of the crankshaft.

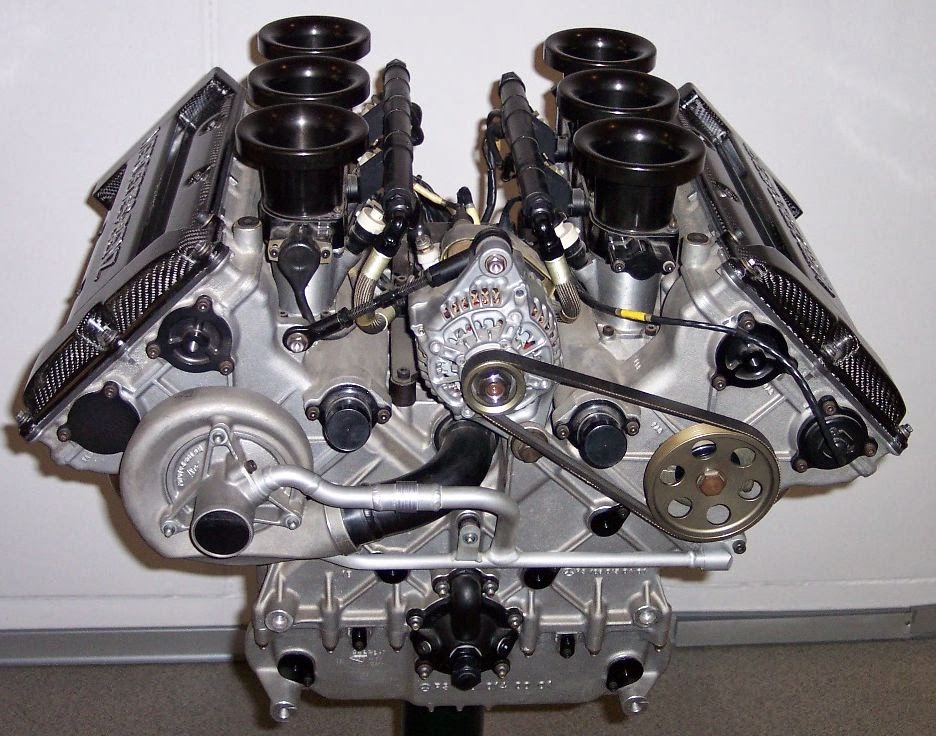

2. V-type engine

An engine with two cylinder banks inclined at an angle to each other and with one crankshaft known as V-type engine.

3. Opposed cylinder engine

An engine with two cylinders banks opposite to each other on a single crankshaft (V-type engine with 180o angle between banks).

4. W-type engine

An engine same as V-type engine except with three banks of cylinders on the same crankshaft known as W-type engine.

5. Opposite piston engine

In this type of engine there are two pistons in each cylinder with the combustion chamber in the center between the pistons. In this engine a single combustion process causes two power strokes, at the same time.

6. Radial engine

It is an engine with pistons positioned in circular plane around the central crankshaft. The connecting rods of pistons are connected to a master rod which, in turn, connected to the crankshaft.

According to air intake process:

1. Naturally aspirated

In this types of engine intake of air into cylinder occur by the atmospheric pressure.

2. Supercharged engine

In this type of engine air intake pressure is increased by the compressor driven by the engine crankshaft.

3. Turbocharged engine

In this type of engine intake air pressure is increase by use of turbine compressor driven by the exhaust gases of burning fuel.

Comments

Post a Comment