Basic Introduction or Principle: We all are aware with the term "Generator". A device which converts mechanical energy into electrical energy is known as generator. This generator makes rotate with the help of some kind of external energy. When this energy extract from the energy of steam, the plant is known as steam power plant. A simple steam plant works on Rankine cycle. In the first step, water is feed into a boiler at a very high pressure by BFP (boiler feed pump). This high pressurized water is heated into a boiler which converts it into high pressurized super heated steam. This high energized steam passes through steam turbine (a mechanical device which converts flow energy of fluid into mechanical energy) and rotate it. Owing to extract full energy of steam, three stage turbines is used which is known as LPT (Low pressure turbine), IPT (intermediate pressure turbine) and HPT (High pressure turbine). The turbine shaft is connected to the...

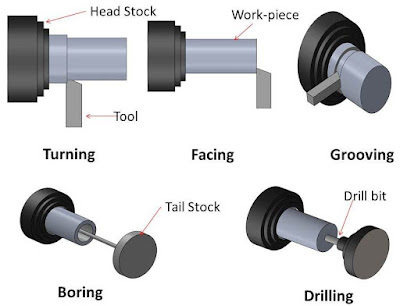

Today we will learn about lathe machine parts, its operation and working. Lathe machine is a basic machine which is used in every metal forming industries. It is combination of many parts which works together to perform a desire function. A lathe machine is used to machine cylindrical work piece which is 360 degree symmetrical form the axis of rotation. It used to perform turning, chamfering, boring, facing, internal threading, shaping, slot cutting etc. on cylindrical work piece.

There are many types of lathe machine but each machine consist some basic part which are essential for its proper working. These parts are bed, tool post, Chuck, head stock, tail stock, legs, Gear chain, lead screw, carriage, cross slide, split nut, apron, chip pan, guide ways etc. These parts work together to obtain desire motion of tool and work piece so it can be machined.

The lathe machine works on basic principle that when the work piece rotate at a constant speed and a tool is introduce between its rotation, it cut the metal. This is basic fundamental of it. The working of lathe machine is explained in later section of this article.

Lathe machine: Main Parts, Operation and Working

We have briefly discussed about parts and working of lathe machine in upper section of this article. Now we will describe it.

Parts of Lathe Machine:

The lathe consist following parts.

1. Bed

It is the main body of the machine. All main components are bolted on it. It is usually made by cast iron due to its high compressive strength and high lubrication quality. It is made by casting process and bolted on floor space.

2. Tool post

It is bolted on the carriage. It is used to hold the tool at correct position. Tool holder mounted on it.

3. Chuck

Chuck is used to hold the workspace. It is bolted on the spindle which rotates the chuck and work piece. It is four jaw and three jaw according to the requirement of machine.

4. Head stock

Head stock is the main body parts which are placed at left side of bed. It is serve as holding device for the gear chain, spindle, driving pulley etc. It is also made by cast iron.

5. Tail stock

Tail stock situated on bed. It is placed at right hand side of the bed. The main function of tail stock to support the job when required. It is also used to perform drilling operation.

6. Lead screw

Lead screw is situated at the bottom side of bed which is used to move the carriage automatically during thread cutting.

7. Legs

Legs are used to carry all the loads of the machine. They are bolted on the floor which prevents vibration.

8. Carriage

It is situated between the head stock and tail stock. It is used to hold and move the tool post on the bed vertically and horizontally. It slides on the guide ways. Carriage is made by cast iron.

9. Apron

It is situated on the carriage. It consist all controlling and moving mechanism of carriage.

10. Chips pan

Chips pan is placed lower side of bed. The main function of it to carries all chips removed by the work piece.

11. Guide ways

Guide ways take care of movement of tail stock and carriage on bed.

12. Speed controller

Speed controller switch is situated on head stock which controls the speed of spindle.

13. Spindle

It is the main part of lathe which holds and rotates the chuck.

Lathe Machine Operation & Working:

Lathe machine is used to cut the metal from cylindrical work piece, and convert it into desire shape. It turns the cylindrical work piece, and during turning a sharp edge cutting tool introduce, which cuts the metal. Its working can be described as follow.

1. A cylindrical work piece fixed to the chuck. A chuck may have three jaw or for jaw according to the requirement. The work piece is at the center or some eccentric according to the process perform.

2. The spindle starts to rotate and set it at desire speed. The spindle speed plays a huge role during cutting. The spindle rotates the chuck and work piece.

3. Now check the work piece is turning properly. If it not set the work piece using dial gauge.

4. Now set the tool at desire feed by moving the tool post and carriage. The feed also play main role during cutting. Large feed may cause unwanted temperature increase.

5. After it tool is introduce between moving work piece at desire feed rate. It cut the metal from work piece. The feed rate is set at the cutting condition.

6. Now all unwanted metal is removed by moving the carriage form horizontally and vertically as desire according to the job requirement. After complete all process we got a well finished job.

7. Lathe can perform turning, boring, chamfering, shaping, facing, drilling knurling, grooving as shown in figure.

Comments

Post a Comment