Basic Introduction or Principle: We all are aware with the term "Generator". A device which converts mechanical energy into electrical energy is known as generator. This generator makes rotate with the help of some kind of external energy. When this energy extract from the energy of steam, the plant is known as steam power plant. A simple steam plant works on Rankine cycle. In the first step, water is feed into a boiler at a very high pressure by BFP (boiler feed pump). This high pressurized water is heated into a boiler which converts it into high pressurized super heated steam. This high energized steam passes through steam turbine (a mechanical device which converts flow energy of fluid into mechanical energy) and rotate it. Owing to extract full energy of steam, three stage turbines is used which is known as LPT (Low pressure turbine), IPT (intermediate pressure turbine) and HPT (High pressure turbine). The turbine shaft is connected to the...

What is a boiler?

A boiler is a closed vessel, which is made by metal, in which water is converted into steam by using the heat energy of fuel. It can generate steam at desire temperature, pressure and the heat generation rate.

According to the A.S.M.E. the boiler is define as " A combination of apparatus for producing, finishing and recovering heat together with the apparatus for the transferring the heat so made available for the fluid being heated and vaporized."

Image Source : http://news.cision.com/fulton-limited/r/fulton-launches-new-range-of-horizontal-firetube-boilers,c9363532

Principle:

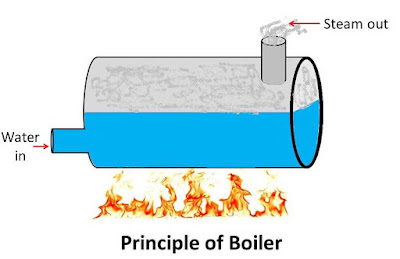

In a boiler, the heat energy of the flue gases transfer to the water through convection. The fuel is burnt in the furnace which produces flue gases. These flue gases pass over the water containing in shell or tube according to the type of boiler. The heat of the flue gases transfer to the water and convert it into steam. This is the basic principle of boiler.

Working:

Boiler is simply a heat exchange in which, water is work as cold fluid and the flue gases works as hot fluid. The heat is transfer from hot fluid to cold fluid through convection which increases the energy of water and convert it into steam.

To understand working of a boiler, considered a container half filled with water. The fuel is burn and the flue gases flow over the container as shown in figure. These gases heat the water and convert it into steam. This steam taken out from a tube situated upper side of the container. As the steam taken out from container, the equal amount of water is feed into the container by the feed valve which maintain the boiler pressure unchanged.

If the steam escaping rate is high compare to water feeding rate, the pressure of the boiler decreases. And if the water feeding rate is high compare to steam escaping rate the pressure of the boiler increases. Thus the boiler pressure is controlled by the fuel supply and water supply of the container. This is the basic working of a boiler.

Also Read : Working of Lancashire boiler

Also Read : Working of Lamont boiler

Also Read : Working of Lancashire boiler

Also Read : Working of Lamont boiler

Function:

The main function of a boiler is to generate steam at desire pressure and desire steam generation rate. A boiler has to provide the space for water, steam, furnace, and safely perform the following function.

1. Generate the steam at desire pressure.

2. The steam generation rate is high.

3. Provide a appropriate surface area to transfer heat from gas to water.

4. Safely operation

5. Convert steam into super heated steam if desire.

6. Avoid the explosion due to high pressure inside the boiler.

6. Avoid the explosion due to high pressure inside the boiler.

Types:

There are many types of boilers. These are as follow.

According to the axis of boiler:

1. Horizontal boiler

2. Vertical boiler:

3. Inclined boiler:

According to fire:

1. Externally Fired boiler

2. Internally fired boiler

According to pressure of boiler:

1. High Pressure boiler

2. Low pressure boiler

According to circulation of water:

1. Forced circulation boiler

2. Natural circulation boiler

According to circulation of gases:

Parts of a Boiler:

The boiler is a combination of many parts which are used to achieve a common function. These parts are divided into two categories. The first one is known as mounting and the other one is accessories.

Boiler Mountings:

The boiler parts which are essential for the safely performance of boiler, or in absence of which the boiler cannot generates steam, known as boiler mountings.

1. Water level indicator:

The water level indicator is used to check the water level inside the boiler. It is used to correct working of boiler. It is mostly fitted in front of boiler. It consist three cocks and a glass tube.

2. Pressure gauge:

A pressure gauge is used to measure the pressure inside the boiler. It is also fitted in front side of the boiler. Generally, Bourden type pressure gauge is used in the boiler.

3. Safety valve:

The safety valve is fitted on the drum. It prevents the explosion due to high pressure in the boiler. It is generally two in number. The safety valve blow offs the steam when the pressure inside the boiler exceeds the certain limit.

4. Stop valve:

This valve is used to control the flow of steam from the boiler to the steam pipe. It opens When the steam require, it shut off when sufficient steam is the steam pipe.

5. Blow off cock:

It is used to blow off mud and water whenever required. It is situated at the bottom of the drum. It is use to empty the boiler, when required.

6. Feed check valve:

It is a NRV (Non Return Valve). It regulates supply of water in drum, by the feed pump. It is fitted to the drum slightly below the normal water level.

7. Grate

It is the space in furnace on which fuel is burn.

Boiler Accessories:

Those parts which are used to increase efficiency of a boiler and boilers can perform safely without these parts are known as boiler accessories. These parts are as follow.

1. Feed pump:

Feed pump is use to pump the water in boiler for continuous working. The feed pump is run by the electricity or by an steam turbine. The steam use to drive the turbine taken by the boiler itself, which increase the boiler efficiency.

2. Super heater:

The steam generate by the boiler is saturated steam. If this steam is use in turbine, it may cause corrosion. So the steam is superheated before taken out for process work. This is done by super heater.

3. Economizer:

Economizer is use to preheat water before it enter into boiler drum. The economizer uses the heat of flue gases to preheat the water. The flue gases coming out from boiler, first passes through economizer and then to atmosphere. It increases the efficiency of boiler.

4. Air preheater:

Air preheat is use to preheat the air. It is preheated by the exhaust gases of boiler. So it also increase efficiency of boiler. The heated air enters into boiler.

Comments

Post a Comment